In 1986, WACO Aircraft Corporation’s first WACO YMF Classic biplane rolled off the assembly line complete with two open cockpits, stacked wings, radial engine, and handcrafted design in faithful homage to a golden age of flight. Based on the design of the popular 1930s biplane and crafted using techniques from the 1920s and 1930s, WACO Aircraft Corporation’s WACO YMF Classic was not a rebuild or a build kit of the vintage aircraft, but rather a modern production with the latest avionics under the original WACO-type certificate, certified by the Federal Aviation Administration, or FAA.

WACO Aircraft Corporation, which was founded in 1983 in Lansing before relocating to Battle Creek, Michigan, would go on to introduce its first YMF Super biplane in 1991 and quickly become internationally recognized for its manufacture and production of high-quality classic biplanes backed by a dedicated team of experienced craftsmen and artisans. There is an attention to detail and passion for flight that emerges in the carefully handcrafted aircraft, where the curving forms and long horizontal lines echo of Art Deco Streamline Moderne aspirations in its fit and finish, capturing the heart and the imagination of aviation-enthusiasts worldwide.

Today, it is known for the WACO YMF-5, which features a 300-horsepower, Jacobs radial engine, two-staggered unequal-span wings, all-weather fabric skins, a composite propellor, state-of-the-art avionics, and a cruising speed of 115 mph available as both a land and an amphibious aircraft. Its second biplane, the Great Lakes 2T-1A-2 by WACO, features two open cockpits, two staggered wings, all-weather fabric skins, cabin heater, a 180-horsepower Lycoming engine, and a cruising speed of 120 mph with the latest avionics options.

In November 2018, Dimor Aerospace Inc., a Florida-based subsidiary of Dimor Aero Gmbh of Germany, acquired WACO Aircraft Corporation as well as the Centennial Aircraft Services Inc., a fixed-based operator and FAA Part 145 maintenance facility—both of which are located at the Battle Creek Executive Airport at Kellogg Field in Battle Creek—committing to the continued success of the FAA-certified, EASA-certified biplane producer. By May, 2019, WACO Aircraft Corporation in collaboration with Ghafari Associates LLC and Walbridge, a Detroit-based construction company, broke ground on an 80,000-square-foot addition in Battle Creek to support the expansion of their operations and to provide a modern, comfortable FBO for their private aviation clientele.

“We were all blown away when we were at the facility and actually saw what this small company in Battle Creek was doing, because these are handcrafted airplanes and we just didn’t know they were making these biplanes with today’s avionics,” said Tom Tooley, AIA, executive vice president of Ghafari Associates based in Grand Rapids, Michigan.

Initially brought in on the expansion project through their long-time partner Walbridge, Ghafari Associates looked to combine the aviation expertise of their Chicago office with the design experience of their Grand Rapids office, an opportunity and collaboration that was a first for the firm, according to Tooley. Featuring two new large service hangars with vintage-inspired facades, a fabrication shop, composites shop, restaurant, FBO, and engineering office space to accommodate for future growth, the project demanded an understanding of the technical aspects of aviation; the intricacies of federal regulations for the engineering, design, and construction at airports; and both commercial and hospitality insights for interior environments and office spaces.

“WACO was acquired by Dimor Aero to continue the owner’s passion for vintage aviation. Dimor is also in the process of building a Junker, which is a historic German airplane,” Tooley said.

“That was the reason to expand the production capacity for manufacturing of these planes, and also add the services and storage component—Centennial—so they can service and store clients’ planes. It really just grew the campus for them from two hangars to four hangars, and added the restaurant and FBO,” Tooley added.

The Battle Creek Executive Airport at Kellogg Field, previously known as W.K. Kellogg Airport, is a regional, general aviation airport owned by the City of Battle Creek within the National Plan of Integrated Airport Systems. It is not only home to WACO Aircraft Corporation and Centennial Aircraft Services, but also the Western Michigan University College of Aviation, Duncan Aviation, Battle Creek Air National Guard, and the FAA Battle Creek Flight Inspection Field Office. In 2019, the FAA ranked the Battle Creek Executive Airport at Kellogg Field the third busiest in the state and 59th out of 256 contract air traffic control towers.

The FAA, which works with state and local governments and other stakeholders in the planning of a safe and efficient system of airports, develops standards for engineering, design, and construction at airports from the airfield pavement, lighting, and surveying data, to terminal facilities, radio control, and beacons. Tooley noted the design and construction process for the expansion project had to meet with those FAA guidelines—as well as airport standards—and influenced elements like hangar height and sightlines for air traffic control.

“What is interesting about working on an airport is you have an air side and you have a land side. The building has to have two front doors, so you are challenged by this very linear element and that linear element then becomes the bridge between existing and new,” Tooley said.

“The linear element is a two-level structure with FBO clients arriving at grade level allowing additional offices and the restaurant above on the second level. The restaurant is open to the public and has become a local favorite with a fresh, local menu and fantastic views of the airport and the facility,” Tooley added.

Sean Ruwart, PE, LEED AP, senior project manager at Ghafari Associates based in Chicago, Illinois, who noted the WACO Aircraft Corporation expansion project was perfect for leveraging the design and aviation expertise of both offices, said as far as technology, it was mainly about air-to-ground communication.

“If a customer is flying in and they want to get a hold of the FBO, they can say, ‘I’m coming in,’ and obviously contact the air traffic controller. There are also some radio antennas that are mounted on the roof that assist with that communication,” Ruwart said.

Ruwart also noted a big piece of the overall design was integrating the air and land components in a way that provided a seamless experience, like intentionally placing large windows to provide a glimpse into the handcrafted process and maintenance of the biplanes from grade-level and the second-floor WACO Kitchen, or providing views out onto the airfield from its open balcony.

“You have the hangar adjacent to the FBO where customers can look out the window and see their plane being manufactured and assembled. We wanted to give the customers an experience and an understanding of the history and the beauty of the WACO brand and production at the facility,” Ruwart said.

“I think another piece to the overall façade is that we wanted to create a campus look, so we didn’t deviate too much from how the existing hangars looked. We wanted to create as uniform a look as possible on the campus,” Ruwart added.

The exterior, particularly for the two new large service hangars, took cues from existing vernacular onsite as well as the largely influential Art Deco and Bauhaus movements that emerged popular in the 1920s and 1930s during what has been called the Golden Age of Aviation. While the styles existed during almost the same period, Art Deco was often characterized by rich decoration and the German-based Bauhaus school of thought reflected a blend of art and craft, featuring simpler forms and technical craftsmanship—a nod to both WACO Aircraft Corporation and Dimor Aero Gmbh, according to Tooley.

“We were looking at old hangars from that time period when aviation first got started and that is where the round form for the hangars came from,” Tooley said. “We looked at Art Deco, but also reached into Bauhaus for the German side and influences, keeping the FBO very modern and clean, but also highlighting the craftsmanship that they use to build these [biplanes] and being able to pull that in both design and material into the building.”

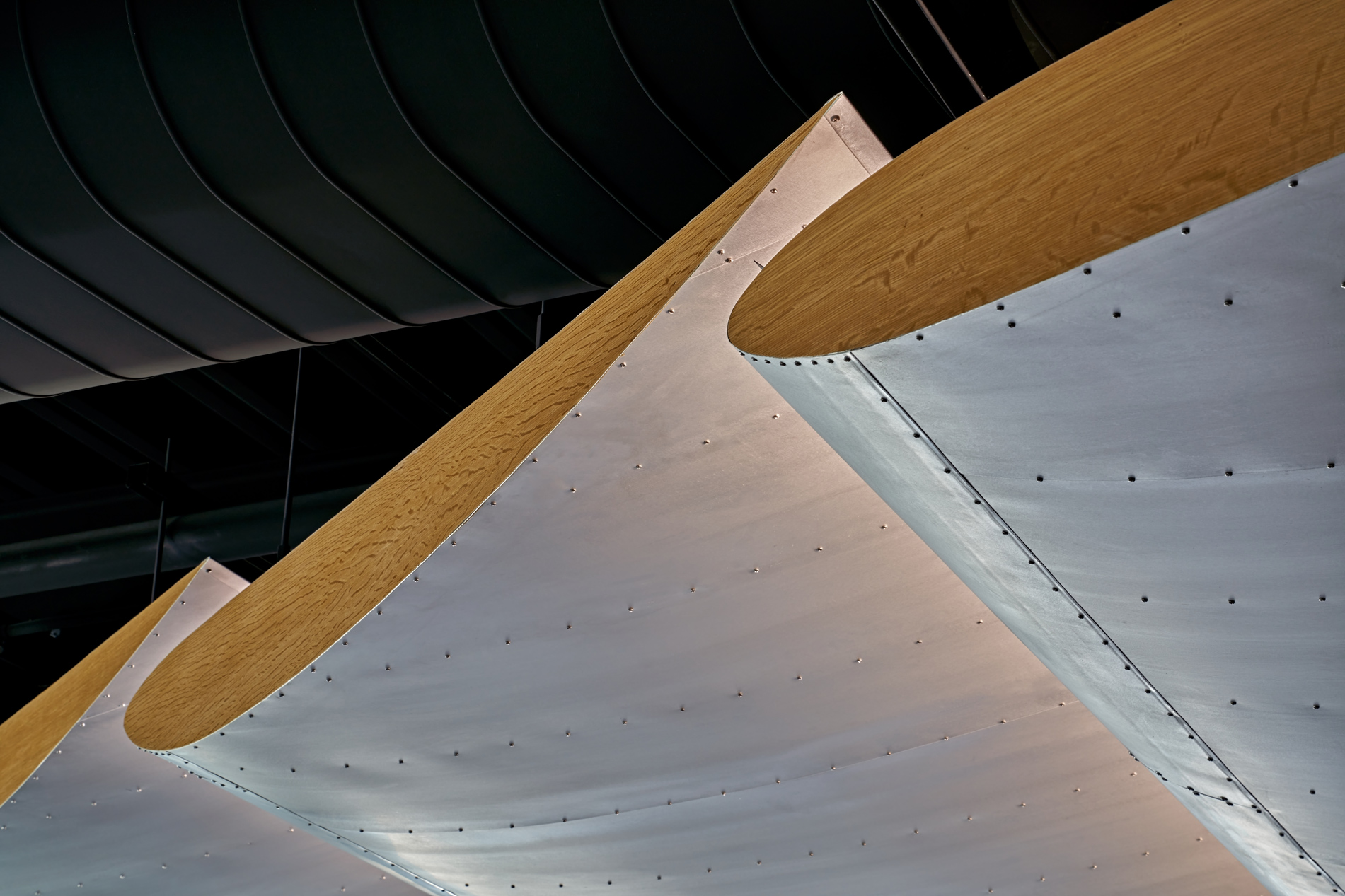

While the hangar interiors are all-white and feature energy-efficient LED lighting where custom paint schemes and interior leathers of YMF-5s and Great Lakes 2T-1A-2s take on an almost sculptural element in a museum-like setting—the adjacent building interiors reflect details and elements from the planes themselves. The planes, which are available in matte, clear, or metallic finishes in roughly 150 base colors, and with interior leathers in more than 80 shades and unique stitch patterns, in a way become a part of the interior experience as much as they are their own bold statement of handcrafted aviation design. With its large observation windows, the boundaries between FBO, restaurant, and office spaces become less defined, as customers and employees can view into the hangars. Other aviation-inspired elements can also be found throughout the facility interior, such as in the floor pattern meant to replicate plane curvatures and in the cabling that is meant to evoke support details on the wings. Tooley noted the design team also worked with WACO to fabricate the ceiling element upon first entering the FBO building.

“It’s a riveted aluminum skin and it’s a series of simulated wings that are shaped to follow the floor plan, but it creates this grand entrance element, and then we pulled the wood element from the trusses that build the wings and started to use that in a ceiling element that leads people through the building and into the railing of the stair,” Tooley said. “Even the light fixtures in the FBO have a tendency to look like propellers.”

Ruwart also noted another interior detail inspired by the production of the WACO biplanes is the wall covering found in the main corridor, which is essentially a large graphic wall showcasing the company’s engineering drawings.

“It’s taken from old blueprints of the WACO aircraft that were blown up and stretched out and applied to the wall so as people are walking through, as customers are going through the main corridor, they can understand the history of WACO. Our intent was that even some of the TVs in that main corridor would document some of the historical timeline of the WACO aircraft throughout its production,” Ruwart said.

For Ruwart, the most distinctive aspect of the expansion project for him is the melding of features of the WACO aircraft implemented into the design of the facility.

“It really does create an experience of the WACO aircraft and I think that is important for customers to see,” Ruwart said. “Design is an experience. It’s a feeling and when you walk into a space, you want it to tell a story and you want it to tell you the history or reflect the history of what is happening in that facility. We wanted to create that positive experience for WACO and its customers.”

To Tooley, design has always been about the balance of art, math, and science, and the process is about making sure the team is listening to the user and using that inspiration to understand what their clients are after and lead them through that path to build a story.

“It is probably why I love architecture, because if I start with a blank canvas, I just look at a blank canvas, but with architecture, you start with a design problem, you are solving a problem and you have a set of constraints to work with and they help form that ultimate design,” Tooley said. “When it really comes down to it, my passion has always been for the user, because when we walk away, it is not our building; it is theirs.”

First published in Great Lakes By Design: In Flight, 2022

Text: R.J. Weick

Photography: Jason Keen